Setting New Standards

About CADflow

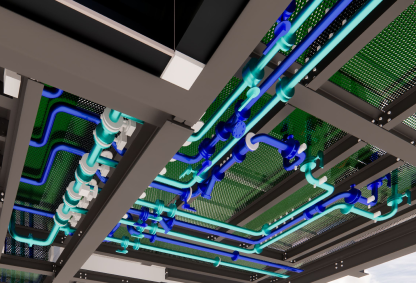

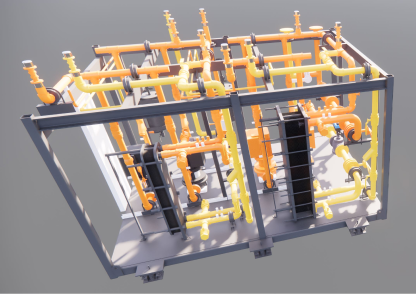

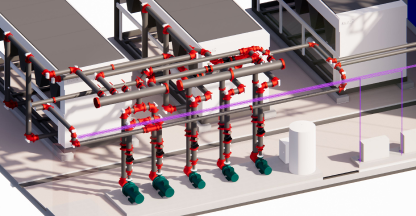

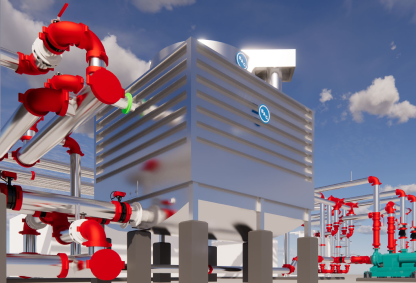

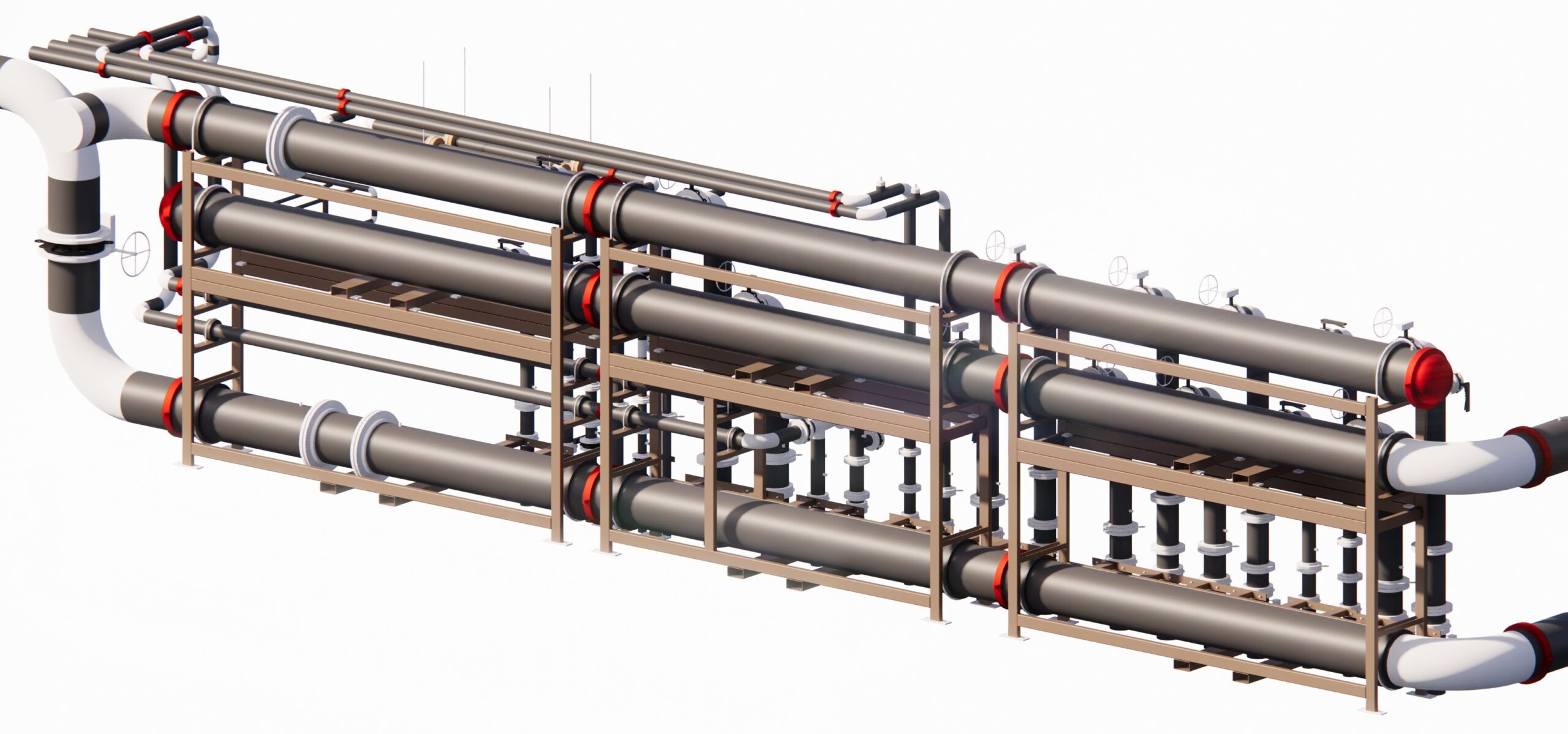

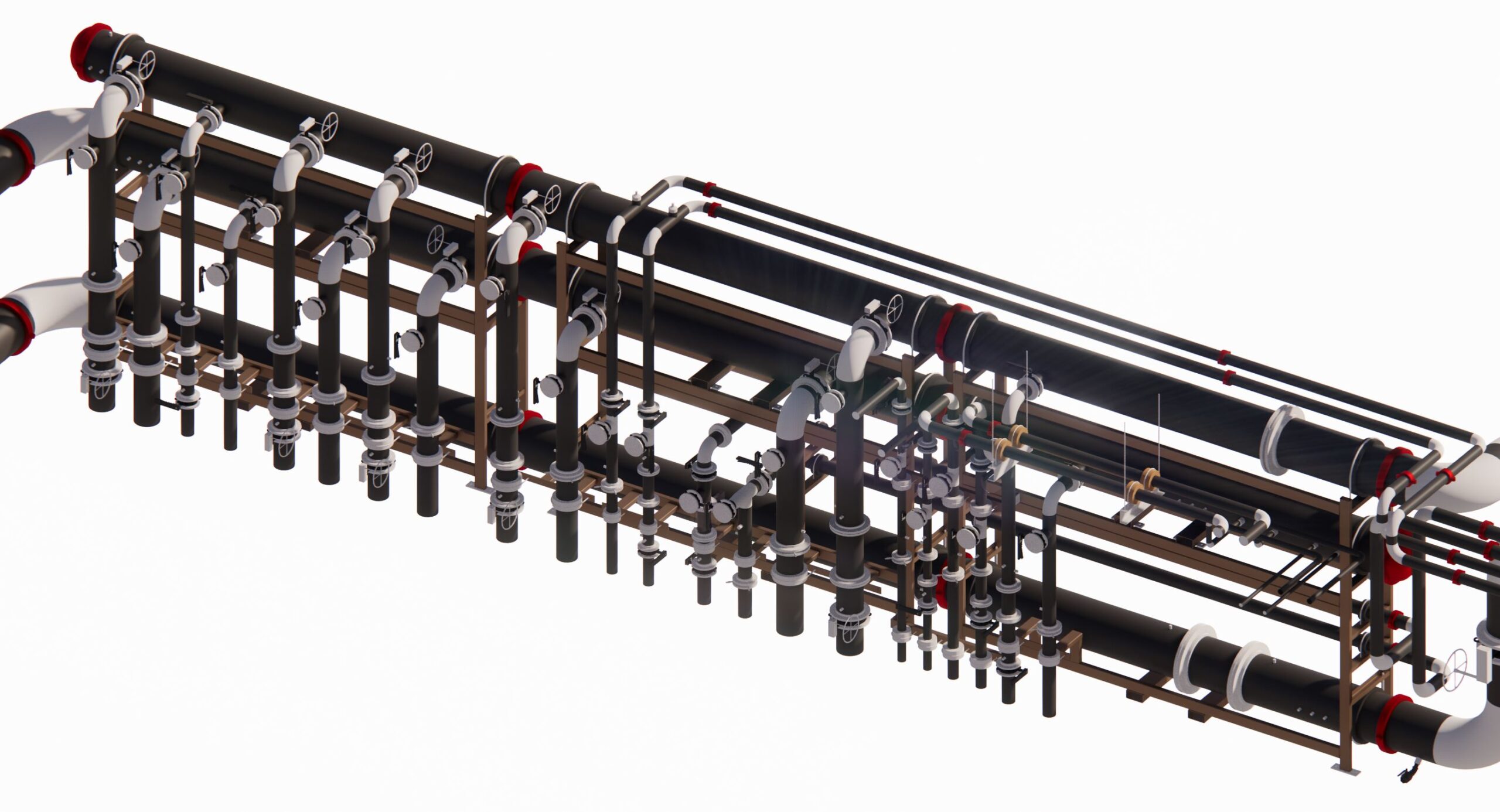

CADflow specialises in Pipework & Prefabrication, offering expert design services tailored to meet your needs. We have vast experience utilising industry leading Revit software to deliver BIM models of unparalleled quality and precision. Our process involves transforming these models into layout and fabrication drawings, ensuring a seamless fabrication and installation process with consistent success.

Managing Director Ben Jones has worked internationally for nearly two decades with large organisations and engineering firms. At CADflow, we pride ourselves on design accuracy and our client focused approach to project management.

CADflow understands the importance of strong communication, we’re a cohesive team working together to achieve optimal success for every project we undertake. We’ll always make ourselves available to take part in design meetings, respond promptly to queries and give progress updates. We’re interested in working with clients who share the same values.

At CADflow, we embrace DFMA, which stands for Design for Manufacture and Assembly. DFMA is an engineering approach that aims to streamline production by optimising designs, minimising parts, and simplifying assembly procedures. By implementing DFMA strategies, we improve product quality, cut costs, shorten lead times, and enhance overall efficiency.

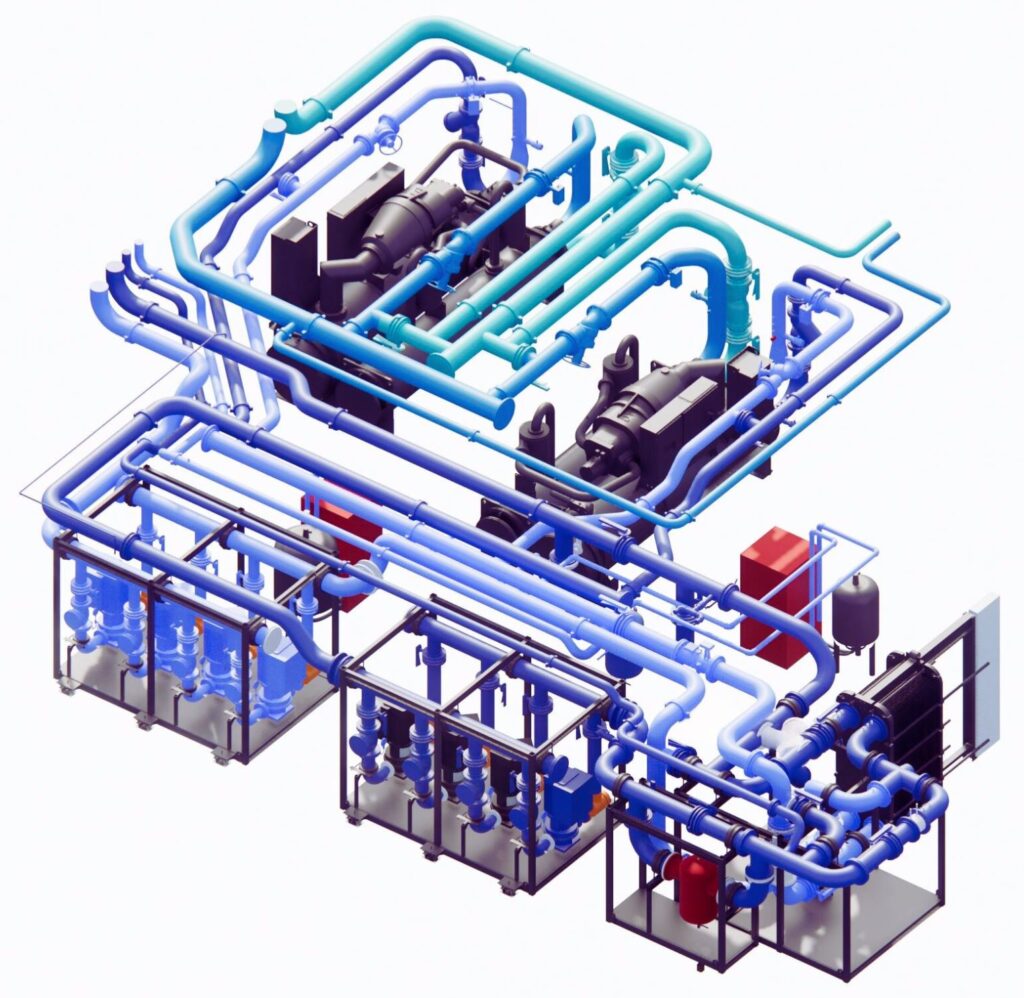

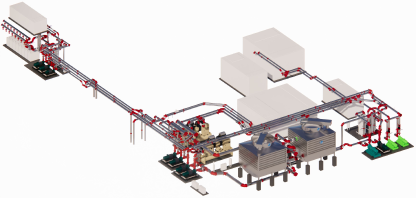

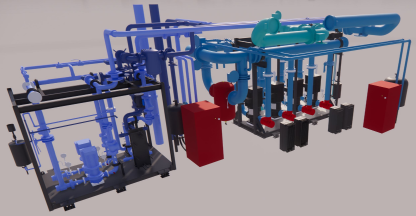

Project Gallery

Frequently Asked Questions (FAQ)

Melbourne.

Yes, we are currently focusing on Clients from Australia, New Zealand, and the United Kingdom. We will be expanding our services to other countries in the near future.

We use industry-leading software Revit to ensure precision and efficiency in our designs.

Yes, we are vastly experienced in all types of Projects including Commercial, Residential, and Industrial.

Our team is flexible and responsive to design changes. We use cloud-based tools that allow real-time updates and collaboration, ensuring that any design modifications are seamlessly integrated into the project.

Prefabrication design involves creating detailed models and drawings for components that are manufactured off-site and then assembled on-site. Benefits include reduced construction time, improved quality control, cost savings, and enhanced safety.

Yes, we offer free consultations to discuss your project requirements, goals, and expectations. This helps us tailor our services to meet your specific needs.

The main information we need is Tech Data, Schematics and any relevant Models. We also provide our clients a ‘Project Requirements’ form to fill out at the beginning of each project.

Please refer to our Blogs page.

Please refer to our Blogs page.